|

Micro-fabricated high-frequency magnetic coils for extreme environments in tokamak reactors.

Role

Student Researcher

Timeline

2022 - 2024

Tech Stack

At the Swiss Plasma Center, the measurement of magnetic fields within a tokamak reactor is critical for plasma stability. These sensors must withstand extreme heat, radiation, and vacuum conditions while maintaining high precision.

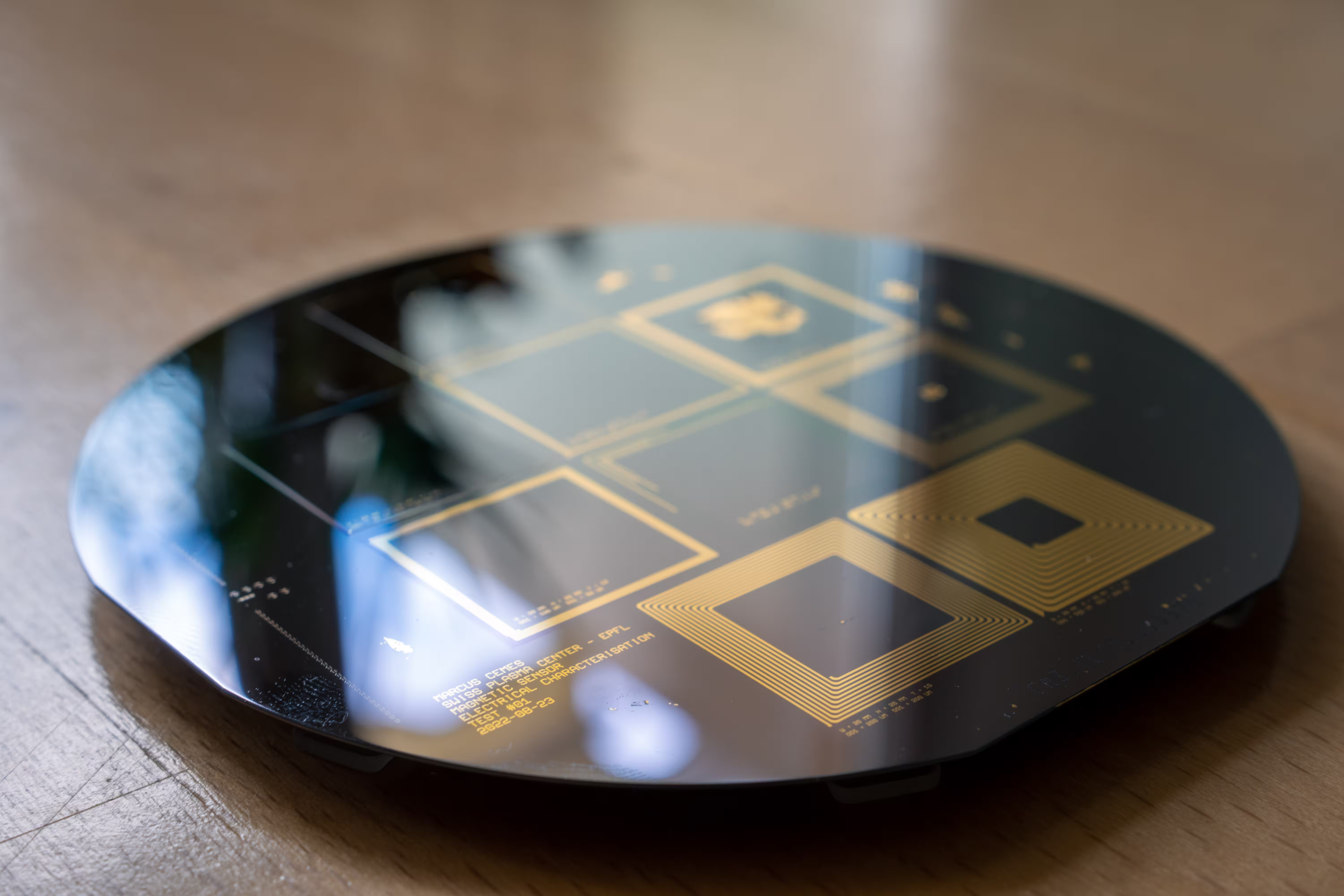

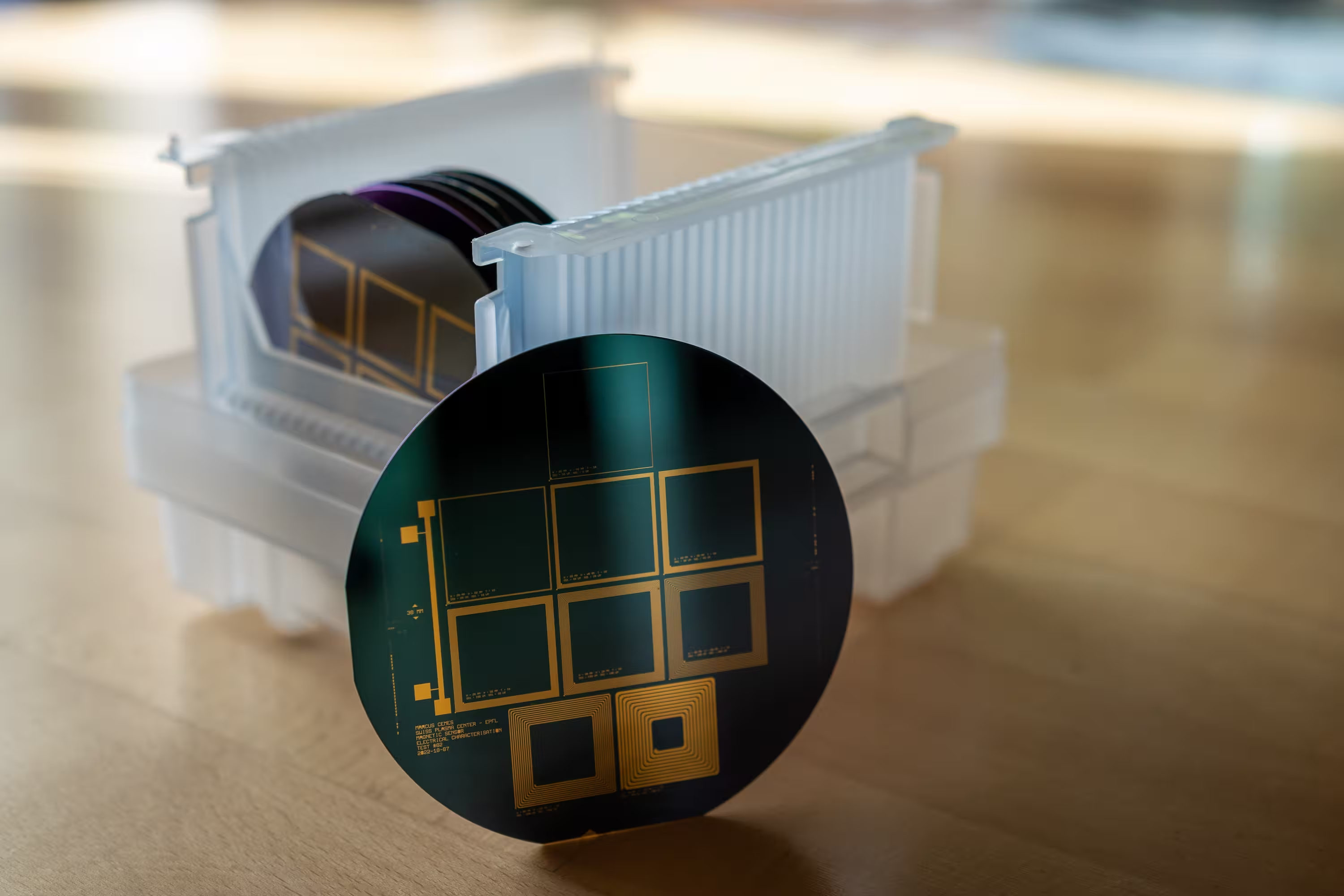

Methodology. Inspired by previous work on Low Temperature Co-fired Ceramic¹ (LTCC), we utilized photolithography techniques typically reserved for semiconductor manufacturing to create large magnetic field sensing coils². This required working in the CMi cleanroom facilities.

Contribution. Designing these complex coil geometries manually was prone to error. I developed a parametric generation tool using Rust and C++ (leveraging the gdstk library). This tool allows researches to quickly and accurately design coil geometries with specific properties, generating GDSii modules to be integrated with the main wafer mask required for the lithography process. I also contributed to the prototyping and testing of these designs, including spin coating, mask aligners, dry/wet etching, PVD, lift-off processes and electrical characterisation.

¹ Testa, D., et al. (2011). Prototyping a High-Frequency Inductive magnetic sensor using the nonconventional, Low-Temperature Co-Fired ceramic technology for use in ITER. Fusion Science & Technology, 59(2), 376–396. https://doi.org/10.13182/fst11-a11653

² Testa, D., Cemes, M., Decaux, E., Lavilla, C., Tanguy, F., & Amor, M. (2025). Conceptual design of inductive magnetic sensors using photolithography processes. Fusion Engineering and Design, 214, 114907. https://doi.org/10.1016/j.fusengdes.2025.114907